Industries requiring heavy equipment such as aerospace, oil & gas, heavy trucking, and mining, among others, have specific needs when it comes to precision components. Whether you’re seeking large-diameter components or industrial transmission parts, it’s important to partner with a manufacturer whose expertise and capabilities align with your demanding specifications.

Avon Machining is an expert supplier of heavy equipment components, with over 40 years of experience in crafting durable industrial parts. Our capabilities include:

- High-precision gears

- Large-diameter CNC machining

- Transmission parts

- Axle shafts

High-Precision Gears

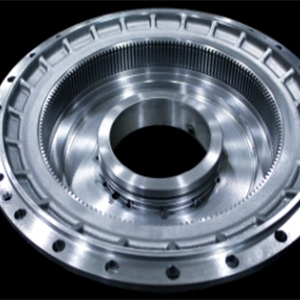

Avon Machining has extensive experience creating high-quality precision gears. Many of these gears are used in transmissions, although they may be used in all manner of industrial machinery requiring drives or gearboxes.

Our high-precision gear capabilities include:

- Spur Gears. Spur gears have straight teeth and mount onto parallel shafts. They may be used in consumer or industrial products, and they are one of the most common types of gears across applications.

- Helical Gears. Helical gearshave teeth that are cut on an angle for quieter and smoother operation. These gears are common in automotive transmissions.

- Sun Gears. Sun gearssit at the center of an epicyclic gear train, which has multiple “planet” gears that rotate around a central sun gear. These planetary gear systems are common components of transmissions.

- Ring Gears.Ring gears contain the other gears of a gear train. The planet gears notch into the ring gear’s internal grooves, rotating inside.

- High Contact Ratio (HCR) Gears. HCR gearsare stronger than standard gears and are excellent for heavy-duty applications.

Some of the many industries that rely on Avon Machining for precision gears include:

- Aerospace

- Defense

- Heavy Trucking

- Construction

- Mining

- Agricultural

- Oil & Gas

Large Diameter CNC Machining

Large diameter CNC machining presents unique challenges. Transporting and positioning large components is difficult, and many facilities lack the necessary equipment to achieve tight tolerances on oversized parts. At Avon Machining, we meet these challenges with ease, while delivering high quality, cost-effective parts that meet your requirements.

The key to our large-diameter machining success is our combination of state-of-the-art equipment with a fully integrated engineering and production control system. Our horizontal lathes can handle parts reaching 80” in length with diameters up to 18”, and our vertical turning lathes can machine even larger diameters up to 61″. We perform these machining services on a variety of common, high-performance metals, including:

- Steel

- Stainless Steel

- Ductile Iron

- Aluminum

- Gray Iron

Drawing on these materials and cutting-edge machinery, we manufacture a broad spectrum of CNC components, including:

- OEM Parts

- Cylinders

- Flywheels

- Rotating Housings

- Hubs

- Carrier Stators

- Torsion Bars

- Adapters

- Clutch Housings

- Precision Shafts

- Pulleys

- Rollers

- Spacers

- Spindles

- Hydraulic Parts

- Threaded Parts

- Drums

- Turbines

These examples, which only represent a portion of our capabilities, are frequently requested by clients from the following industries:

- Defense

- Aerospace

- Construction & Mining

- Heavy Trucking

- Agriculture

Learn more about our industry-leading CNC capabilities here.

Transmission Parts

Gears are not the only critical components that Avon provides to automotive, construction, trucking, and mining clients. We also provide durable transmission parts, including:

- Bearing Races

- Rotors

- Speed Sensors

- Stators

- Brake Drums

- Shafts

We draw on our cutting-edge machinery to achieve precise tolerances on machined components up to 5 feet in diameter, allowing us to accommodate transmissions for on-highway, off-highway, and mining vehicles.

For these projects, we work with a variety of standard machining metals, including:

- Steel

- Stainless Steel

- Ductile Iron

- Aluminum

- Gray Iron

As part of our turn-key engineering solutions, we select each metal based on application needs, machinability, surface finish, and cost. Our goal is to guide customers from initial planning through shipment, offering expert advice on every aspect of the design process. We offer actionable feedback and collaborative production management to ensure that you are completely satisfied with your transmission components.

Axle Shafts

The primary role of an axle shaft is to transmit motion from the transmission to a vehicle’s wheels. These simple yet critical elements must be made with precision from high-quality materials if they are to reliably perform well while bearing massive amounts of weight.

To withstand the sheer weight of vehicles and cargo, as well as the added stresses of movement, axle shafts are typically made from durable metals like:

- Medium carbon alloys (containing chromium, nickel, or molybdenum)

- High-grade steel (SAE 1541, 1050, 1055, or 1039)

We forge and heat treat our steel axles using induction coils to yield hard, solid surfaces with a pliable, ductile core. The combination maximizes equipment lifespan and prevents cracking under the strain of transmitting motion.

Avon Machining can produce axle shafts with diameters up to 18″ and lengths up to 80″, all of which undergo thorough quality testing to ensure superior performance. Our capabilities also include steel axle shafts with bearing-quality surfaces.

We proudly manufacture axle-shafts for the following industries:

- Defense

- Aerospace

- Construction & Mining

- Heavy Trucking

- Agriculture

Learn more about our equipment, process, and materials for axle shafts here.

Splines and Teeth

Rotating mechanisms such as gears use splines to transfer rotary motion and energy. A splined shaft is lined with evenly-spaced teeth that sit parallel to the shaft’s rotational axis. These teeth may either be straight-sided or involute forms depending on the shape of the gap, or root, between the teeth. A straight-sided tooth has a flat face in between the teeth while an involute form has a notched root.

Most external spline shafts have a complementary internal spline shaft, which has an inverse design. The internal splines fit within the external shaft’s teeth, locking together to transfer rotational energy. Together, splines and teeth form the foundation of all rotational devices, including gears.

At Avon Machining, we rely on state-of-the-art shaping machines, hobbing tools, and cutting tools to achieve precise external and internal spline connections that adhere to stringent NBN-DIN–BS-AGMA and NF standards. We manufacture splines up to 36″ in diameter with shafts up to 52″ in length, including both straight-sided and involute forms.

Learn more about Avon Machining’s spline and tooth capabilities by clicking here.

Trusted Components From Avon Machining

At Avon Machining, we are known for providing high quality, complex, and precise medium to large machined parts. We continually achieve tolerances and geometries that our competitor’s simply can’t match, drawing on over 40 years of machining experience and state-of-the-art equipment. To learn more about our products and services, contact us or request a quote today.